Prototype Casting

When it comes to developing your ideas, we’ve got the most effective prototyping options for whatever component you are designing—not to mention our team of in-house experts that will help you choose the right one for the job.

Building Better Prototypes

By definition, a prototype is the first, preliminary model that allows design engineers the ability to quickly and efficiently explore their designs, test their performance, and craft even better components. After all, production components will be modeled and copied from this initial part.

When the prototype is the building block essential to the success of a project, don’t be forced to choose a prototyping supplier based on time and cost. So much can be learned from a prototype’s function, the need for a quality prototype is critical. When designing metal components, an exact replica of your final part is the best prototype you can get.

That is where we come in. Request a quote for prototypes here.

Rapid Prototyping

Crunch time may mean different things for different projects, but one thing’s for sure, nobody wants unforeseen surprises.

Stopping to prototype your design, evaluate its feasibility, and ensure its productivity might be critical to your product’s ultimate success. But at this stage of a product’s lifecycle, timing is essential. A delay of weeks can result in lower sales and lost market share.

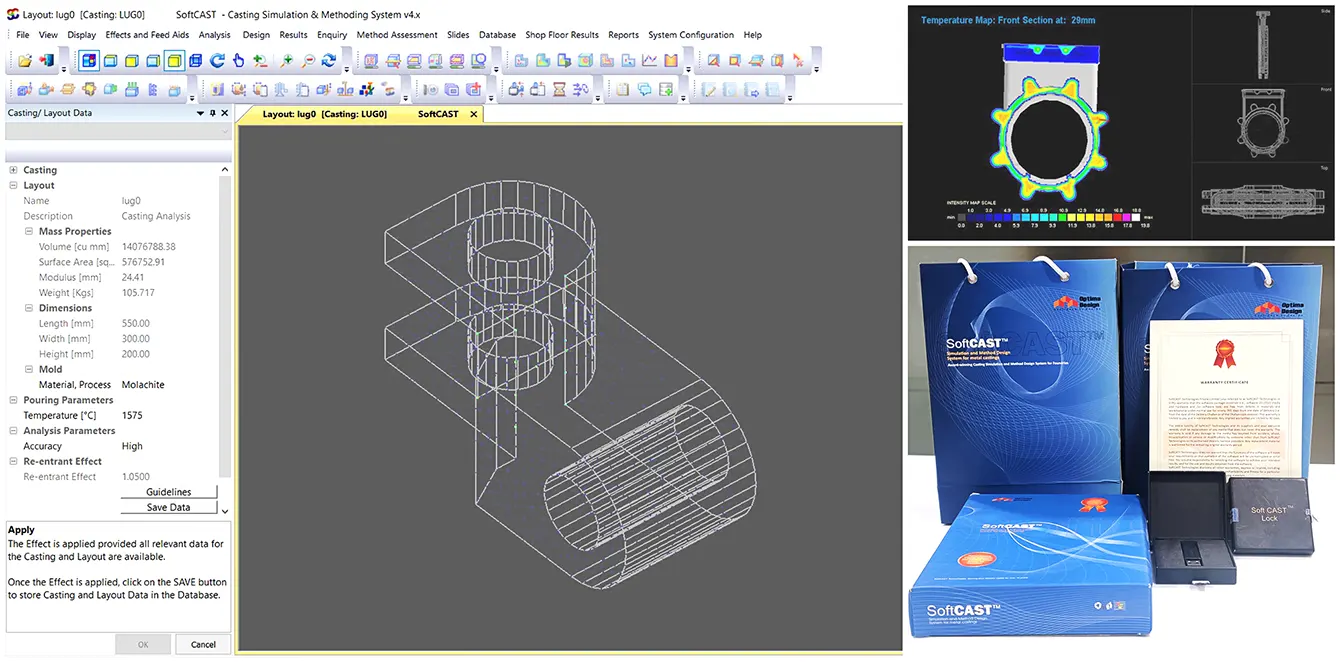

We use SoftCast Simulation software for our new developments and analyze the metal flow and other parameters for the soundness of the castings before they are processed. It helps us to provide robust gating to the part and make a significant assembly of the sampling shell to give quality castings at one go.

Super Quali Cast’s Capabilities

When it comes to developing your ideas, we’ve got the most effective prototyping options for your component. Our prototyping capabilities include:

- 3D printed wax patterns immediately processed into fully functioning metal components.

- Rapid tooling using your part geometry, produced manually to reduce lead time and cost.

- Specially formulated proprietary wax to ensure dimensional accuracy.

- The ability to prototype utilizing any of our metals—you are not limited by material offering.

- Capable of any secondary operation that the customer requires including: assembly, heat treating, welding, plating, painting, and more!

- Prototype Lead Times

Best of all, we can create prototypes in as little as five days. Our average tooling lead time is three to five days. Lead times can vary based on complexity of the part and overall project needs.

Quick lead time will NOT affect the quality of the part.

Cast Prototyping

We know that finding a supplier who can constantly and consistently supply prototypes can make or break your business. Investment cast prototyping is efficient in the overall cost and time of the project. The best thing is, you do not have to compromise quality for time or cost. Our in-house team of knowledgeable engineers are constantly thinking outside of the box to ensure our customer’s designs become a successful reality. Let us help you succeed.